Serving Los Angeles & Orange Counties. Located in Huntington Beach, California.

Elliptical Sheet Metal Manufacturing is a precision sheet metal manufacturing shop. Located in Huntington Beach, California. Offering shearing, turret punching, press brake, hardware installation, soft metal rolling, line grain finish, TIG and spot welding, and complete part assembly. With the use of our equipment, Elliptical Sheet Metal Manufacturing is able to provide quality manufacturing to our customers large and small, nationally and internationally from prototype to production. Elliptical Sheet Metal Manufacturing has in-house capabilities to manufacture parts out of aluminum, steel, plastic copper and stainless steel.

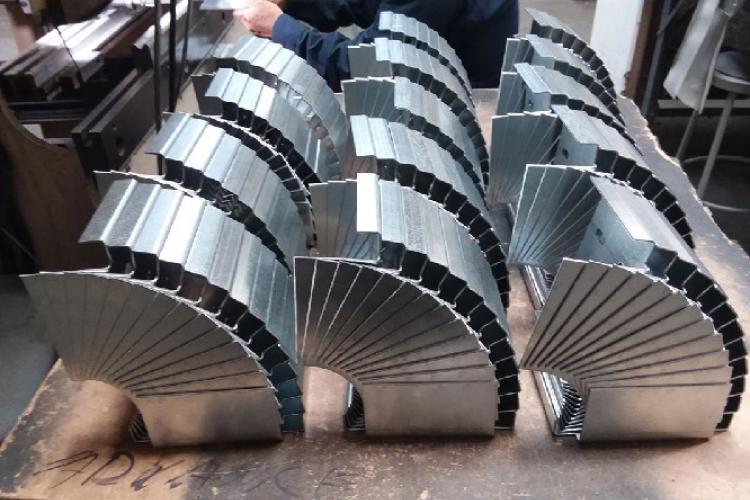

There are three basic types of bending on a press brake, each is defined by the relationship of the end tool position to the thickness of the material. These three are Air Bending, Bottoming and Coining. The configuration of the tools for these three types of bending are nearly identical. A die with a long rail form tool with a tip that locates the inside profile of the bend is called a punch. Punches are usually attached to the ram of the machine by clamps and move to produce the bending force. A die with a long rail form tool that has concave or V shaped lengthwise channel that locate the outside profile of the form is called a die.

The process in insertion of a particular connector or rivet type of nut or connector.

Basically Shearing is the process of cutting or die cutting sheet metal into consistent pieces. A starting point for sheet metal products. Pressure is applied to the sheet metal to create a break point.

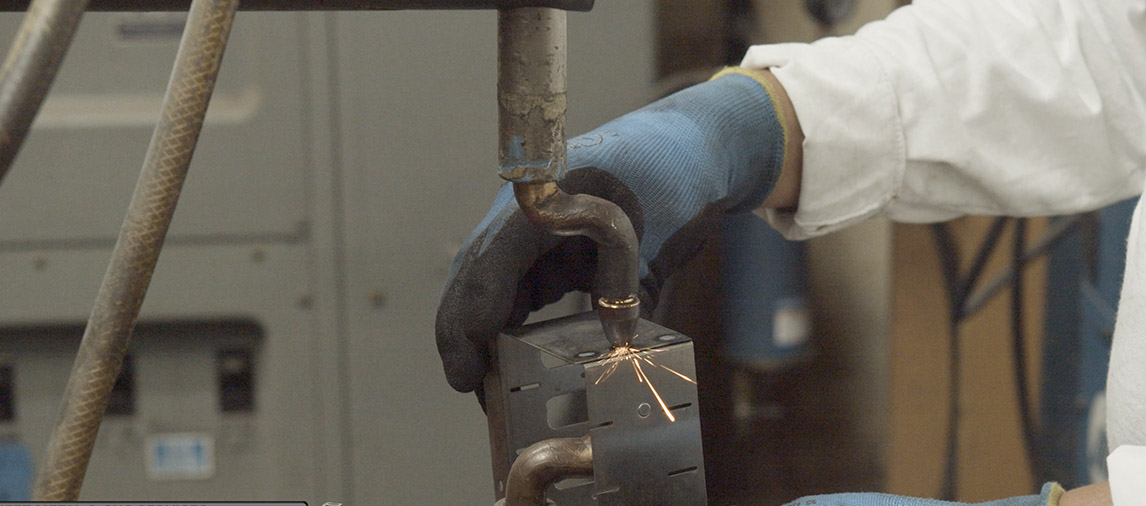

Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet.

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium). Manual gas tungsten arc welding is a relatively difficult welding method, due to the coordination required by the welder. Similar to torch welding, GTAW normally requires two hands, since most applications require that the welder manually feed a filler metal into the weld area with one hand while manipulating the welding torch in the other. Maintaining a short arc length, while preventing contact between the electrode and the workpiece, is also important.

Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. The attractive feature of spot welding is that much energy can be delivered to the spot in a very short time. That permits the welding to occur without excessive heating of the remainder of the sheet.

Mechanical deburring is a deburring process that mechanically grinds a burr off of excess sheet metal parts or rolls the edge of a slit or sheared metal burrs into itself.